Current State of 3D Printing in Furniture and Design

Evolution and Innovations

In recent years, 3D printing has made enormous strides, overcoming the technical limitations that initially held back its widespread use:

- technological limitations: in the past, 3D printing for furniture was often considered impractical due to technical limitations, such as lack of variety in materials and low structural strength of finished products;

- high cost: the technology was expensive and therefore difficult to adopt on a large scale;

- Aesthetic appearance: 3D printed products lacked sufficient aesthetic appeal, limiting their appeal to consumers.

Today, thanks to new advanced materials, such as biopolymers and other recyclable solutions, it is possible to produce durable, lightweight and sustainable furniture. These new materials along with improved manufacturing techniques enable the creation of complex, customized designs, paving the way for a new era of innovation in the furniture industry.

Sustainability and Efficiency

Sustainability is a major driving force behind the adoption of 3D printing. The ability to produce on demand reduces waste and the environmental impact associated with overproduction. In addition, 3D printing consumes less energy than traditional methods, making it an environmentally responsible choice.Customization and Creative Freedom

3D printing offers an unprecedented degree of creative freedom, allowing designers to experiment with innovative shapes and structures that would be impossible to achieve with traditional methods. Mass customization is now a reality, allowing consumers to create customized products that reflect their personal style and needs.Trend Company

3D printing is particularly relevant when used with a vision and operation typical of the circular economy. Model No. Furniture prints exclusively with patented plant-based resins, which produce 80 percent less greenhouse gases, uses 52 percent less nonrenewable energy, and does not mechanically degrade when recycled and reused.

Design-build company Aectual brings the circular approach of 3D printing to the systemic level.

With packaging giant Tetra Pak and with the support of Recon Polymers BV. (materials recycling)and Innolab Chemistry (compounding), Aectual has created an ecosystem to channel one of the largest waste streams in the packaging industry-the aluminum compound that makes up 25 percent of every beverage carton-into a collection of 3D printed planters, panels, and interior furniture.

After use we take our products back, crumble them up and reprint them. Hedwig Heinsman (Frame Magazine).

Industrial Digital Printing: a Synergy with 3D Printing

Industrial digital printing allows custom textures, colors and images to be applied to complex surfaces, enhancing the aesthetics and properties of finished products.Mass Customization

This printing technique allows products to be customized at scale without sacrificing production efficiency. In furniture design, for example, it can be used to apply custom textures, colors and images to complex surfaces, offering a degree of customization that meets individual consumer needs.

- Applications: interior design, custom furniture, unique decorative elements.

- Benefits: reduced production time and cost compared with traditional decorating and finishing methods

Efficiency and Cost Reduction

Industrial digital printing enables rapid and low-cost production of complex items, eliminating the need for traditional tools and equipment. This is especially useful in prototyping and limited series production, where flexibility and speed are essential.

- Economic benefits: reduction of tooling costs and minimization of waste materials

- Environmental impact: reduced ecological footprint through efficient use of materials and on-demand production.

Materials Innovation

Digital printing is also innovating in the field of materials, enabling the use of advanced inks and substrates that offer unique properties such as scratch resistance, chemical resistance, or even integrated electronic functions.

- New materials: conductive inks, photochromic substrates, biodegradable materials.

- Advanced applications: creation of intelligent or interactive surfaces, design elements that respond to the environment or the user.

Integration with 3D Printing

Digital printing can be integrated with 3D printing to create products that combine the unique features of both technologies. For example, 3D printed components can later be decorated or functionalized using digital printing techniques to enhance aesthetics or material properties.

- Hybrid components: 3D printed products with customized surfaces by digital printing.

- Custom mass production: combining additive manufacturing and digital printing to produce highly customized furniture and accessories.

Trend Company

Layerloop 3D , is a young Italian company that is becoming a key player in the 3D printing industry with a focus on cutting-edge technologies and a strong focus on sustainability.

Layerloop offers unique solutions in the 3D printing market, characterized by:

- Expanded print format: Layerloop’s printers support some of the largest print formats available, ideal for mass production and creation of large objects.

- Waste reduction: tilt-axis printing technology minimizes the use of support structures, thus reducing material waste.

- Versatility of materials: the company is a leader in the use of a wide range of engineering polymers (from PLA to carbon over 10 materials in the assortment) that are particularly suitable for creating durable, high-quality furniture.

Future Opportunities and Challenges of 3D Printing in the Furniture and Design Sector

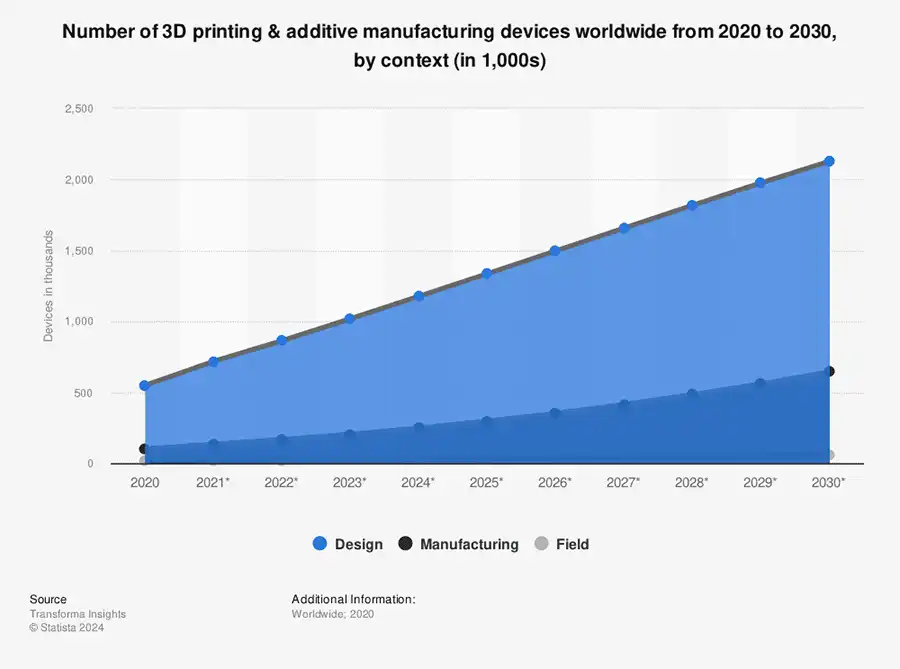

- Growth in demand: the demand for customized and sustainable furniture is growing; 3D printing offers a viable solution to meet these needs.

- Consumer acceptance: as awareness about sustainability increases, consumers are more likely to accept and adopt 3D printed furniture.

- Market expansion: the 3D printed furniture market is expected to continue to grow, also driven by innovations in materials and technologies.

- Integration with digital technologies: the integration of 3D printing with other digital technologies, such as artificial intelligence (AI), Internet-of-Things (IoT) and digital printing, could further transform the way furniture is designed and produced to interact with people and the environment.

- Consumer Education: there is a need to educate consumers about the benefits and possibilities of 3D printed furniture.

Conclusion

3D printing and industrial digital printing are also finally finding their place in the world of furniture and design, offering new opportunities for customization, efficiency, and sustainability.

Companies that adopt these technologies could enjoy a significant competitive advantage in an evolving and growing market driven by demand for sustainable and customized products.