In previous articles on integration and the future of printing, we discussed how printing technology can help customers and their clients develop new products and new business opportunities

We are also aware that sampling to prove technical feasibility is not enough: it is also necessary to have “market feasibility” (known as “market validation”), which “validates” whether or not there is a market for that product or service. Because the risk is that:

having invested financial resources and purchased machinery thinking that the idea could be useful to someone or based on “promises” from customers that were not kept

having produced a machine, perhaps custom-built, used little or not at all, parked on the company premises and taking up space

With the contribution of our Innovation Manager Andrea Radin, who supports companies in innovation projects, and feedback gathered from companies and experts in the printing industry, we have identified the following requirements:

Customers’ customers want to ‘touch’ the product in order to evaluate it and make decisions (not just see it on paper)

in the B2B market, there is a need to produce small batches in order to open up the market to new products, involving one’s customers

quickly understanding whether there is a market or not: today, the time required to produce a prototype using traditional channels (mass production) is lengthy, and equipment costs must be taken into account (even for small quantities)

This has led to the creation of the new “MVP SERVICE”, which aims to help companies validate the market for a new product or business idea before manufacturing and/or purchasing a machine

In particular, the service aims to help businesses to:

understand whether there really is a market

don’t waste time and money

evaluate and/or make choices based on data and feedback from customers and the market (not just on intuition)

make a mistake “early on” and close the project if there are no positive responses, avoiding wasting money on something that the market does not want

gather data and useful knowledge to develop new products and services that customers are willing to purchase

Below, we will discuss the following topics:

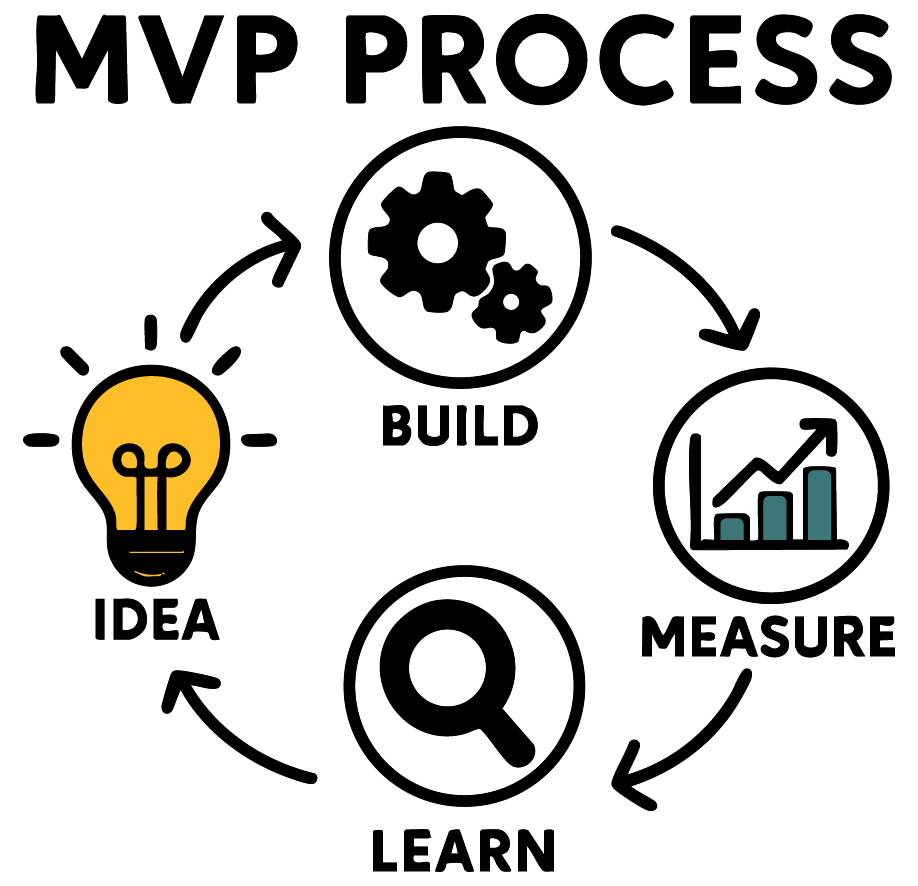

WHAT IS AN MVP (Minimum Viable Product)

First of all, let’s take a look at what an MVP is, even though you can find various definitions, courses and useful guides online.

In summary, an MVP:

- It is a version of a product with minimal functionality, but sufficient to be used by real customers and obtain feedback

- It is an economical method of validating business ideas before making substantial investments:

- An MVP allows you to save on costs and limit risks, as activities that prove commercially unviable can be easily terminated

The main objective of an MVP is to test the business idea, gather feedback and validate the product’s feasibility before investing in full development and/or making substantial investments

It also helps to:

- Test product hypotheses faster and with minimal resources.

- Accelerate the learning process regarding the dynamics of your market.

- Reduce time wasted on engineering design.

- save on costs and limit risks, as activities that prove commercially unviable can be easily terminated

- Generate a basis and process for the development of new products and services

- Demonstrate the ability to build the product proposed to the customer

- Build a brand quickly (if you are developing a business different from your current one)

WHY IS AN MVP IMPORTANT IN THE B2B MARKET?

Below, we share some of the main reasons why an MVP is important:

- Professional customers want to see samples and evidence before committing themselves

- You can test the willingness to pay a premium for low print runs

- If the tests do not go well, change your mind or redesign without causing significant damage

- Check the stability of repeat orders, which is essential for amortising the investment

- Get real references that give you credibility

- You can start with a lightweight model (outsourcing and order management) and scale up only if the business proves profitable

- Reduce time to market:

- For example, invest less than €10,000 to see if it makes sense to spend €500,000

- Build relationships with customers before launching

- Start with real orders, not just assumptions

SER.TEC'S MVP SERVICE

MVP service consists of supporting the company in the creation of the MVP with the aim of helping companies validate the market for a new product or business idea before production and/or purchase of a machine

Ser.tec will support the company during the MVP development phases, specifically the following phases:

Objective-> Verify that the product is technically feasible:

- Produces product samples (small runs, e.g. 50-100 pieces)

- assess quality, colour rendering, production times and any parameters required by the sector

Objective -> Understanding how many customers are ready to pay immediately:

- Take the samples to potential target customers (e.g. local food producers, delicatessens)

- Make a concrete offer:

- Minimum print run

- Estimated Price

- Delivery times

- Minimum print run

- You get:

- Letters of intent

- Pre-orders

- Possibly small pilot supply contracts

Objective -> Refining the offer:

- Collect customer feedback (quality, price, packaging, delivery)

- Improve any critical points:

- materials,

- printing process

- graphics

- integration of internal and/or external processes

- delivery times

- materials,

ADVANTAGES OF THE MVP SERVICE WITH SER.TEC

Those who do the sampling already have information, ink type, settings, and tested support equipment that have passed the technical feasibility test and are therefore ready to make an MVP:

-

if you turn to others, there is a risk that the result obtained in the sampling and feasibility testing phase will NOT be achieved

-

The process takes longer because in some cases you have to “start from scratch” by redefining the machine’s settings and configurations

-

there are settings on the machine that are the result of experience and expertise that others do not have

-

supports and equipment were prepared, enabling sampling to be carried out

-

Data and specifications useful for the construction and configuration of the machine are collected

-

those who design and build the machine have information that they would traditionally only collect after the machine has been sold (the customer participates in the co-design), change their minds or redesign without causing enormous damage

-

- The quality of the sample will be identical to the pilot production

- You can demonstrate that the machine is capable of producing exactly what you promise to customers

- The quality of the sample will be identical to the pilot production

-

- The manufacturer often has a demo department or an application laboratory where it produces small runs

- Supports you in fine-tuning print parameters (colour management, materials, speed)

- The manufacturer often has a demo department or an application laboratory where it produces small runs

-

- You can validate not only the product, but also setup times, operating costs, reliability, and waste

- In practice, the manufacturer helps you simulate production on a small scale

- You can validate not only the product, but also setup times, operating costs, reliability, and waste

-

- Many manufacturers offer pilot production at reduced cost or included in the purchase agreement as part of the trial

- Sometimes you can deduct the cost of samples from the final price of the machine

- Many manufacturers offer pilot production at reduced cost or included in the purchase agreement as part of the trial

AND AFTER THE MVP?

If the MVP process is successful, the following paths could be taken:

1) Purchase of a machine or development of a custom machine/line:

the data and specifications collected will provide useful information for configuration and, if necessary, design and construction

the customer will play an active role in configuration and possible co-design, accelerating the adoption and use of the technology

2) Scalable business approach:

A company may initially evaluate outsourcing production, or adopt it as a standard process, particularly for:

a question of numbers (it’s a new business venture)

a production issue (there is no organisational structure)

an initial strategic choice and subsequent internalisation (if certain numbers are exceeded)

If this route is chosen:

We will suggest any partner companies that we believe have the necessary production capabilities and meet the requirements defined in the MVP

We will provide you with the documentation containing the necessary requirements to transfer them to the partner you have identified, in compliance with confidentiality requirements

should you subsequently decide to internalise the process, we will provide support as described in point 1)

3) Internalise the MVP process within the company

If the company has an R&D department, once it has learned the process of developing an MVP, it could consider internalising it during the prototyping and market validation phase:

equipping itself with printing technology with features and settings that are in line with the development of products and the sector to which it belongs

integrating printing technology with 3D printing technology to complement the former

in the event of developments involving new products and MVPs that fall outside the company’s core business and/or type of materials, you may contact us only in these cases

In this way, Ser.tec’s MVP service becomes an MVP for businesses

In summary, the MVP Service can help to:

- Test product hypotheses faster and with minimal resources

- Accelerate the learning process on the dynamics of your market

- Reducing wasted time in engineering design

- Save on costs and limit risks, as activities that prove commercially unviable can be easily terminated

- Generate a basis and process for the development of new products and services

- Demonstrate the ability to build the product proposed to the customer

- Build a brand quickly (if you are developing a business different from your current one)

For further information about the service, please fill in the form below: